What’s New in Ansys 2024 R1

February 22, 2024

Using AI to Elevate Simulation Technology

April 8, 2024Though new product development boils down to seven clear steps, the process is anything but simple. Each stage requires enormous amounts of time and resources to ensure the design is safe, let alone viable. While failure plays a critical role in finding the precise iteration you take to market, each faulty prototype adds more time before launch and more expenses in development. However, the evolution of product development simulation technology revolutionized this complex process, allowing engineers to instantly test models and fix issues before building a single prototype.

How Does Product Development Simulation Technology Work?

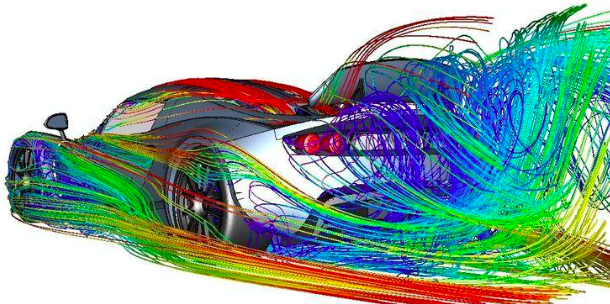

Simulation software builds virtual models of your product design, incorporating material properties, physics, and even user behavior. These models are then subjected to various "what-if" scenarios, using algorithms to mimic real-world conditions. You can simulate fluid flow, stress on structures, thermal behavior, and even consumer interaction without needing to build a physical prototype. After the simulation runs, you can see which parts of your design worked, failed, and can be improved.

Product development simulation technology works in three stages.

- Model creation: Using various tools, you input a digital twin of your product design into the simulation software. Pay close attention to details to get the best results from the simulation.

- Physics engine: Once the design is complete, the software utilizes an algorithm to breathe life into your product and digitally test every aspect of it. Some software, such as Ansys Fluent, specifically examines fluid dynamics, while others test structure, thermodynamics, or acoustics. The goal is to find any aspect of your product that doesn’t work and illuminate it before you build a prototype.

- Results report: The simulation produces data on your digital prototype, highlighting stress under load, fluid flow patterns, temperature gradients, and more. After interpreting this data, you have clear next steps for further design development to prepare it for manufacturing.

Pros and Cons of Simulation in Product Development

The pros and cons of using simulation technology in product development are straightforward, but their implications are significant. Ultimately, this software is an investment that increases the efficiency of your operation. Check out our favorite parts of utilizing a simulation model below.

- Faster development: Skip costly and time-consuming physical prototypes, bringing products to market sooner.

- Reduced risk: Identify and address potential problems early, eliminating costly late-stage redesigns.

- Improved performance: Optimize designs for better efficiency, strength, and user experience.

- Enhanced collaboration: Real-time simulation tools allow teams to iterate and make decisions jointly, even remotely.

While it seems like an obvious choice to utilize simulation software in your business, there are several drawbacks you should consider before deciding to invest.

- Software cost: This can be expensive, especially for advanced functionalities.

- Model complexity: Building and validating accurate models requires expertise and can be time-consuming.

- Limited testing: Not all real-world phenomena can be perfectly simulated, requiring physical prototype testing in some cases.

How to Use Product Development Simulation Technology

Simulation technology is not limited to one specific role in product development. Engineers utilize these models in several areas, allowing them to refine their designs to near-perfection.

- Early-stage exploration: Iterate on rough ideas quickly, identifying potential flaws and exploring design variants.

- Detailed design optimization: Refine geometry, materials, and assembly techniques to maximize performance or minimize cost.

- Virtual prototyping: Test functionality and user experience, identifying ergonomic issues or usability problems before physical prototypes are built.

Product Development Simulation Software Applications

Technically, any industry that utilizes prototypes as a significant piece of their product development process can apply simulation software to their operations. However, simulation technology is most useful in applications where prototyping is expensive and time-consuming - such as all-terrain vehicle development. These areas frequently use this software to fine-tune product functionality.

- Structures: Strength analysis, thermal analysis, durability, topology optimization

- Fluids: Battery simulation, hypersonics, multiphase flows, reacting flows and combustion

- Electronics: Antennas, radio frequency interference, signal integrity, electronics cooling

Product development simulation is a powerful tool that helps engineers create better products more quickly than through prototype creation. While it has limitations, its benefits in terms of cost, speed, and performance make it an essential component in the modern engineering toolbox. If product development simulation software is the solution that will elevate your product design process, let us help you find the right option to fit your specific needs. Contact our support team and get started today!